Search the Community

Showing results for tags 'labor rate'.

-

With labor rates going up, one concept me also need to consider is multi tier labor rates. For example, performing jobs on heavy trucks is different than work on a Honda Civic, or Toyota Corolla. Also, if you do complicated computer work, electrical and driveability, that requires your top tech with the most expensive tools and training. And those jobs have no part profit. Shouldn't this be billed at a higher labor rate? Do you have a tier labor rate strategy? I would like to hear from other shops.

- 6 replies

-

- labor rate

- labor profit

-

(and 2 more)

Tagged with:

-

The fear of raising prices, both in labor and part margins, always brings an element of fear. This is totally understandable. However, that fear may not be real. The first strategy when pricing is to ensure that you build value in what you are selling. If the perceived value is low, price becomes important. If the perceived value is high, price begins to fade as an issue. Additionally, understand your key profile customer. You know who they are. They are those that throw their keys on the service counter and say, "Fix it, I'll be back at 5pm to pick it up, and no need to call me for authorization." Remember, you cannot be all things to all people. The bottom line here, is truly the bottom line. You need to charge the right price that ensures you earn a profit. Now, don't misunderstand what I am saying here. Raising prices to overcome inefficiencies in your business is not a sound strategy either. If your production levels are not where they need to be, don't automatically look to fault your techs. First, look for bottlenecks in the service staff, not charging the right labor hours, too much discounting, and not performing enough high profitable jobs. Your thoughts?

- 7 replies

-

- labor

- labor rate

- (and 6 more)

-

Repair shops that have done the math, know what their labor rate needs to be. However, are they leaving money on the table when performing some jobs, such as complicated driveability, electrical work, and other computer-related work? Shouldn't we base the labor rate on certain jobs by the technicians that are assigned to those jobs? In other words, if you have a drivability / electrical tech that is also the highest paid in your shop, shouldn't the jobs he or she performs be billed at a labor rate based on his/her pay scale?

-

- labor rate

- labor profit

-

(and 1 more)

Tagged with:

-

Many shop owners have increased their labor rates in the past year or so. That is great news. Now, what's your next move? Anyone who knows me knows that, in my opinion, in general, we have been too cheap for too long. But, determining your labor rate is not the only consideration to attaining a profitable business. What about productivity, efficiency, keeping expenses in line, gross profit, and net profit? What are you doing to ensure you are meeting the financial needs of your business and also paying your employees the money they desire?

-

Part 2 of our labor rate discussion in the automotive aftermarket industry. Our panel emphasizes the importance of setting labor rates based on the shop's own expenses and profitability, rather than comparing them to competitors. They also stress the need for regular labor rate increases and educating staff about the financial aspects of running a shop. They address fear and mindset issues that can affect labor rates and overall success. The episode provides valuable insights and advice for shop owners in effectively setting and managing their labor rates. Chris Cotton, AutoFix Auto Shop Coaching, Chris Cotton Weekly Blitz Podcast. Listen to Chris’ previous episodes HERE Rick White, President and Lead Coach for 180BIZ, Listen to Rick’s previous episodes HERE. Dave Schedin, CompuTrek Automotive Management Systems. Dave’s previous episodes HERE Show Notes: Build Your Labor Rate From The Ground Up Part 1 [THA 276]: https://remarkableresults.biz/remarkable-results-radio-podcast/a276/ Where the Money Goes – The $100 Lesson [THA 210]: https://remarkableresults.biz/remarkable-results-radio-podcast/a210/ Labor rates should not be set based on competitors (00:02:10) The importance of setting labor rates based on the shop's own expenses and profitability, rather than comparing them to competitors. Educating staff about where the money goes in the business (00:03:18) The need to teach employees about the various expenses and costs involved in running a shop, to help them understand the labor rates and the owner's income. Fear and mindset issues affecting labor rates and success (00:05:02) The fear and mindset issues that can affect labor rates and the overall success of a shop, and the importance of addressing these issues before setting labor rates. The importance of financials and owner thinking (00:07:46) Discussion on the prevalence of shop owners not having up-to-date financial statements and the need for owners to transition from technician thinking to owner thinking. Raising the Labor Rate (00:15:40) Discussion on the importance of raising labor rates and providing value to clients. Labor Rate and Value (00:17:19) Exploration of flipping the conversation from price to value and the curse of knowledge. Labor as Time vs Value (00:18:05) Insights on how labor is often tied to time, but should be based on value and the skills of technicians. Setting a Higher Standard (00:23:11) Discussion about the importance of qualifying customers and setting a higher standard for the shop's services. Firing Customers for Excellence (00:24:03) Exploration of the concept of firing customers who compromise the shop's level of excellence and professionalism. Running the Business Like a Business (00:25:58) Importance of charging correctly, controlling the schedule, and making every car count to improve the shop's profitability and efficiency. The impact of increasing labor rates on gross profit (00:31:37) The relationship between increasing labor rates and gross profit. It explains that when a technician's pay is increased, the labor rate must also be raised to maintain the same gross profit percentage. It highlights the importance of understanding the math behind labor rates and setting them proactively. The need to compete with other industries for skilled technicians (00:33:42) The challenges of attracting and retaining skilled technicians in the automotive industry. It compares the benefits and compensation offered by other industries, such as Target and emphasizes the need for competitive labor rates to attract and retain talent. It also highlights the importance of providing tools and benefits to technicians to create a profitable and sustainable industry. Building a profitable business (00:42:42) The significance of being profitable and setting labor rates that allow for a 20-25% net profit, as well as the importance of love and grace in running a successful shop. The importance of making changes now (00:44:27) The need to make changes in labor rates immediately instead of waiting and encourages shop owners to trust the advice of coaches. Thanks to our Partners Shop-Ware and Delphi Technologies Shop-Ware: More Time. More Profit. Shop-Ware Shop Management https://getshopware.com/ Delphi Technologies: Keeping current on the latest vehicle systems and how to repair them is a must for today’s technicians. http://DelphiAftermarket.com Connect with the Podcast -Join our Insider List: https://remarkableresults.biz/insider -All books mentioned on our podcasts: https://remarkableresults.biz/books -Our Classroom page for personal or team learning: https://remarkableresults.biz/classroom -Buy Me a Coffee: https://www.buymeacoffee.com/carm -The Aftermarket Radio Network: https://aftermarketradionetwork.com -Special episode collections: https://remarkableresults.biz/collections Click to go to the Podcast on Remarkable Results Radio

-

I am hearing more and more about shops using a Labor Matrix to increase labor profit. I have been a long time proponent and have used different labor tiers. For example, we worked on passenger vehicles and heavy trucks. The labor rate was higher for an F500 Dump Truck than it was for a Honda Civic. The labor matrix is a different, it allows your business system to factor in more hours for either longer jobs, vehicles over 20 years old, or any other criteria you decide. For example, if the labor for a job is 8 hours, that job may be billed with an additional 10%, making the job 8.8 hours, not 8. I would like to hear from shop owners using this strategy and tell about the impact on their labor profit.

-

Do you recall episode 49, about the Automotive Industry Benchmark Report? Well, its release is fast approaching! Today, Hunt goes deeper into the origins of the report, the questions posed, and a sneak peek at some (surprising) discoveries. Nuanced relationships, direct or inverse, between different variables and metrics in the automotive industry. Linking Labor Rate and Profit: One key highlight from the report is the insight on the Overall labor rate and its correlation with profit. Were there notable differences between different locations? Sales vs. Profit Growth: We also explored a vital question: Is there a direct link between escalating sales and an increase in profit as a percentage of sales? Our findings might surprise you. Thanks to our partners, NAPA TRACS and Promotive Visit NAPATRACS.com and GoPromotive.com Paar Melis and Associates – Accountants Specializing in Automotive Repair Visit us Online: www.paarmelis.com Email Hunt: [email protected] Get a copy of my Book: Download Here Aftermarket Radio Network Click to go to the Podcast on Remarkable Results Radio

-

Many shops have increased their labor rates the past year or two. For too many shops, they have been too cheap for too long. However, speaking to shop owners, their labor rates, even though higher, are still not where it needs to be. Have you raised your labor rates this past year or so? And do you think the raise was enough to keep pace with increased expenses, inflation and the increase in employee pay?

-

My first post hello to everyone, I'm a new shop owner preparing to have a grand opening in a couple of months. A little bit about myself I was first GM certified in 1987 and ASE master certified in 1990 And work for dealership until 2000 'a shout out to Scanner Danner i'm one test away from being master certified again' When I entered into EMS and fire service As a paramedic until covid Vaccination restrictions force me from my job, but that's another story. I've been running my part time shop during this time keeping up with my training any equipment Trying to provide an OEM Quality of work using OEM service data and scan tools. My question is what is the best Warranty/ Insurance can I get to provide protection for myself and my customers to cover In the event there is a part failure or a mistake on my part that may Have led to disastrous results? Example may be a timing belt or chain breaks that I install That now exploded the engine or Heater core start leaking a week after I install it.Another question is how much should I be charging for my parts and should that percentage be from what I pay for the part or from what MSRP It's for the part, I'm sure I have many more questions in the future. Just trying to do right to myself and to my customers. Thanks in advance Scott.

-

For the first time in a VERY LONG time, I see a lot of positive news with regard to labor rates. More and more shop owners and managers are crunching their numbers and increasing their labor rates to better ensure their companies achieves a profit and also to be able to pay their employees what they deserve. Profit is needed in order to build for the future and to be able to attract quality people. I really think that this is perhaps the best time in our recent history to revisit your labor rates and bottom line and adjust your rates accordingly. Have you adjusted your labor rates recently, or plan on it?

- 55 replies

-

- labor rate

- labor profit

-

(and 2 more)

Tagged with:

-

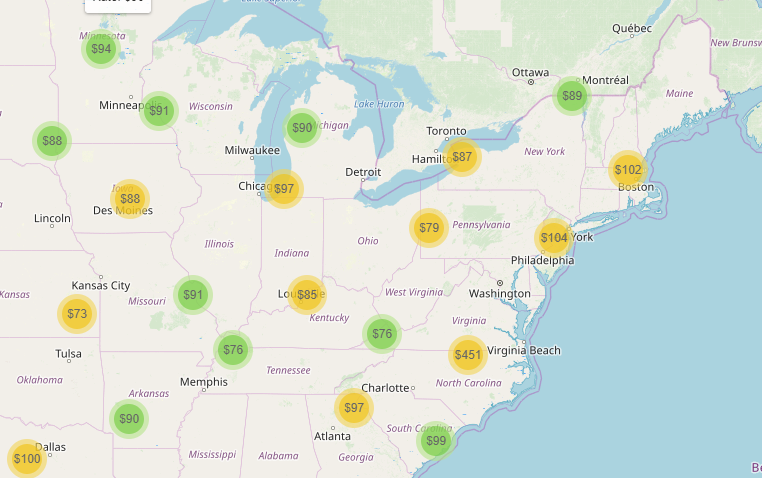

We now have a nice tool available to all premium and platinum members under the tools menu, where you can view labor rates entered by our members on an easy to use map, similar to our member map. This is designed to give you an idea of where you are vs the market in your area. As you zoom in, the circle averages open up to more specific areas. If you aren't currently a subscribed premium or platinum member, you can upgrade here.

-

Last week, I had an interesting conversation with a shop owner friend of mine. He told me that he does not mark up his parts as much as he once did, mainly because of pushback from customers. He states that Google, Amazon, Rock Auto, and others, have hurt that part of the business. I don't want to debate that fact right now, but what I told him is that It doesn't matter how you arrive at your required profit, but you need to maintain profits. If you concede on your part margin, then the only way to maintain your required Gross and Net Profit is to increase your labor rate. Your thoughts and opinions? I would like to know what other shops are doing with part margins these days.

-

I couldn't find a way to reply to your R&W article, so I'm making a separate post. Being in transmission repair, our labor is in different world that G/R. We use book time which is always more than actual time. Our labor efficiency is always more than 100%. It was my job to keep the bays full for maximum efficiency. 150%+ was not uncommon. The only time we dropped below 100% was when I couldn't keep the bays filled. The better I did with marketing, advertising, and promotion, the higher the efficiency. For me, maximum labor efficiency relied on me more than the staff themselves. My staff worked their butts off when the work was there. As far as pricing goes, as of 2015, we were at $125/hr. For canned jobs, we would have just a fixed fee on labor. When calculating the fixed fee, I would use $125/hr. in the calculations. I feel blessed because most customers have no idea of what a transmission costs until I tell them. The vast majority of them just go, "When will it be done?" Our sales procedure included a YouTube video of our findings and an estimate written in stone. It was a pretty bullet proof sales procedure. Unlike G/R, I didn't have to build value because the video said it all. Most people have no idea what's inside a transmission or what's involved until I show them via video.

-

The second video at the bottom of this page will help members to calculate a labor rate. While this was specifically designed for dealerships, a lot of the same principles can be applied to our shops. No need to see what others are charging, we charge off our costs. https://chriscollinsinc.com/training-videos

-

How much do you value your time? Your employee's time? Are you making your decision on your labor rate based on data? My expert panel breaks down a mathematical and strategic way to understand the labor rate that delivers your profit goal. To view the charts and presentations my guests have prepared, make sure you head to my carm capriotto youtube channel or find the link on the show notes. Once you see the math your decision to set a profitable labor rate will be smarter and easier. Dave Kusa, owner of AutoTrend Diagnostics in Campbell, CA. Listen to Dave’s other episodes HERE. Bill Haas, Owner of Haas Performance Consulting, Listen to Bill’s previous episodes HERE. Key Talking Points Your labor rate is an expression of how much you value your time. Raising my labor rate was the worst decision I ever made. Said no one ever! Productivity and profitability per technician Make decisions based on data Prove that your labor rate is right Does your team understand where the money goes? “If you don’t share, they don’t care” Connect with the Podcast Aftermarket Radio Network Subscribe on YouTube Visit us on the Web Follow on Facebook Become an Insider Buy me a coffee Important Books Check out today's partners: More Time. More Profit. Shop-Ware Shop Management getshopware.com Click to go to the Podcast on Remarkable Results Radio

-

What's your houlr labor rate and where are you located? We're currently at $95 in Texas

- 89 replies

-

- labor rate

- hourly labor rate

-

(and 1 more)

Tagged with:

-

@JerryK Hi Jerry, in the Shop Labor Rate thread, you posted 3 labor rates, regular, euro and Pre-1975 cars. I find it interesting that you've set your labor rate very high for these cars. It either means that you don't want those, or it's more expensive to work on them, so you charge more, or it is a specialty skill set that you possess and thus it's a more valuable service, or you are building in an inherent storage fee due to the extended time it takes to get parts, etc or ? I'm interested to understand your thinking regarding this particular rate. Also, why is 1975 the cutoff date? We've been working on a number of older cars, and I've taken the approach that it's a time and materials job. If it takes me 3 hours to remove the stuck drums off of your old car, then your brake job will cost more. If I above-normal spend time looking for parts, then this is billable time too. We shouldn't absorb the added difficulty of rust, age, etc. Maybe I'm approaching this incorrectly. I took in a 1984 project car on Friday... non-standard engine, but newer, bubba's electrical wiring mess, etc, but overall in good shape. We started with 5 hours of labor to assess and possibly fix. It's partly a test to see if he's serious on fixing the car. P.S. I live in Plano, but my shop is in McKinney. In my previous life, I worked not far from your shop.

-

Got your attention? Please read on... In case you were hibernating the last year and half, you had to notice all the increases around you. From food, gas, utilities, taxes, insurance, etc., etc., etc. Not to mention all the training and tool investment we must make from now on, to remain in the business. I have been preaching this for decades: As an industry we don't charge enough, especially when it comes to labor. While there are ways to increase labor dollars, for example: becoming more productive, making sure that we charge for complex testing and driveability; Base labor rates have to factor in as the most important KPI in your business. Do the math, get help from a coach if you need help calculating your labor rate. A real Down and Dirty calculation: If you have one tech and you pay this tech $35 per hour ($42 loaded), then this tech has to bill $140 of labor for every hour worked. ASSUMING THIS TECH IS 100% PRODUCTTIVE. DISCLAIMNER: THIS IS A REAL DOWN AND DIRTY QUICK CALCULATION, SEEK ADVICE IF YOU WANT A MORE ACCURATE REQUIRED LABOR RATE.

-

- 1

-

-

- labor rate

- kpis

-

(and 2 more)

Tagged with:

-

The other day, a local fellow shop owner, was complaining to me that his plumber just charged him $225 labor for a house call. My response was, "And why do you have an issue with that?" I know this plumber; he is very successful, in high demand in the area, does great work and provides a VALUBALE service. Does this sound familiar? You bet....sounds like you and your business!!! When the day comes that all of us truly know what we are worth and charge for it, that will be the day when all us raise the level of the auto industry, begin to attract more people to us, pay our employees better, build for our future and go home with the pay we deserve. I know this is going to cause controversy....so let's start the conversation.

- 2 replies

-

- 4

-

-

- labor rate

- effective labor rate

-

(and 2 more)

Tagged with:

-

For those with bodyshops, here is some interesting reading: http://www.bodyshopsolutions.com/WordPress/?p=111 bodyshopsolutions.com/WordPress/ John Shortell I’ve taken a part time job working at an independent body shop close to my home writing estimates and supplements and harassing insurance companies. I’ve been at it for a few months now and up until recently I haven’t seen or heard from a Progressive appraiser. Finally, several weeks ago, I had a customer who was hit by one of Progressive’s insureds. Because I’m in a different area of the state now, I’m unfamiliar with the local appraisers. More importantly, they are unfamiliar with me. What fun! First let me admit that I was spoiled working at a high line dealership body shop. Those evil rich drove nice new cars that demanded nice new OEM parts. Now all I see are Honda’s and Hyundai’s. Old ones at that. I’ve never seen so many junk cars in my life. But I guess the poor have to drive too. Anyway, I had a customer who was hit by a Progressive insured. I wrote an estimate and asked the customer to make arrangements to meet the Progressive appraiser here at my shop. Progressive people hate that. They’d rather look at the vehicle somewhere else. Any where I am not. When the Progressive appraiser showed up I knew there would be trouble. He looked to be about 12 years old. He fit Progressive’s archetype for their ideal appraiser: young, naive and no experience in the collision repair industry. His estimate was several hundred dollars less than mine. No surprise there. But it was a small repair, and that several hundred dollars amounted to about 30% of my estimate. Of course, the labor rate was an issue, but what really got me wound up with this moronic “blend within the panel” crap. I basically told the kid he could take his “blend within the panel” and have his first sexual experience with it. I wasn’t going to accept it. There were some other issues too, and it all added up to the 30% deficiency. I was beginning to lose my cool because this prepubescent putz couldn’t figure out how to meet my bottom line, so I told him to do what a lot of other appraisers do: make something up and put it on the estimate. Of course, I was being sarcastic, but being so young, this kid didn’t understand the sarcasm and took offense to my suggesting he commit fraud. Well at least the kid is honest. I asked the kid for his appraiser’s license number and the name of his supervisor and explained that I would be filing a complaint with the insurance department, which I did immediately after he left (And don’t we all know how effective that was). I told the customer not to worry about the difference–I would take care of it. I had her sign a repair authorization, a direction to pay and a power of attorney in case I had to sue the bastards. Working at a dealership I never had the opportunity to sue an insurance company because the owner didn’t want the trouble, but now that I’m working at a small independent shop, the owner is willing to go after insurers who don’t play nice. I spoke with the kid’s supervisor over the phone about the situation. For the record, she was very pleasant, just like talking to sweet high school girl. I didn’t meet her in person, but by the sound of her voice she was another Progressive clone–too young and inexperienced in anything to be dealing with these issues. But she promised to look into it. I knew I was wasting my time, and I was. After three days of haggling, the young girl managed to come up with another hundred dollars. She was still a couple of hundred short. I explained to her that I was going to sue her insured for the balance. She responded with a perky “OK” like I had just asked her if she wanted to go hang out at the mall. She was trained to perfection. Great job Progressive behavior modification department! With little effort I was able to locate the guy who hit my customer and promptly mailed him the following letter: Dear Mr. XXXXX, On November 29, 2007 you were involved in an accident with XXXXXX, damaging her Honda Civic. Mrs. XXXX brought her vehicle to us for repairs. Your insurance company, Progressive, refused to pay the amount needed to properly repair Mrs. XXXXX vehicle. Mrs. XXXXX has given us her Power of Attorney and we are collecting the remaining balance directly. The total repair cost was $xxxxx, but Progressive has only agreed to pay $xxxx. Your insurance company has left you owing us $xxx. Your liability insurance is supposed to cover all damages up to your coverage limit, but ultimately you are responsible for any damages not covered by your insurer. We have filed a complaint with the Connecticut Department of Insurance, and we suggest you do the same. If you need help filing the complaint we will be happy to assist you. Progressive has already refused to pay the balance. If you do not pay the difference we will be forced to bring the matter to small claims court. Please contact us to discuss this matter, and for payment options. Our phone number is xxxxxxxxx. Enclosed is a copy of our invoice, paperwork showing what Progressive is willing to pay, and a copy of the Power of Attorney signed by Mrs. XXXXX. Sincerely, John Shortell A few days later I received a phone call from Mr. XXXX. He wanted to discuss the matter. I explained the situation to him in more detail, and he agreed to pay the balance owed and then deal with his insurance company. I again offered to help him in any way I could with filing a complaint with the insurance department or recovering the money from Progressive. He didn’t take me up on the offer, but he did send a check the next day. I’ve yet to hear from him or Progressive so I have no idea if he was reimbursed or not. I do know the gentleman was not too happy about having pay for repairs to someone else’s car after he had been paying premiums for liability insurance. Something tells me Mr. XXXX will be finding someone else to send his hard earned money to for insurance in the near future. I fully expected to have to go to small claims court. I knew Progressive would not give in, and I never expected the insured to cough up the money so easily. I feel sorry for the poor bastard. But I’ll be damned if I will become a cheap whore just because Progressive is too profit driven to treat my customers fairly. It’s ironic. Progressive was started by a left wing socialist. The name Progressive is not a coincidence. This nut job and his dope smoking kid, who recently stepped down from running the company, preached the progressive movements dogma, and heavily funded many of its whacked out causes. Progressives are supposed to be more fair than the evil rich. They are supposed to care about the little guy and scorn the evil corporations, yet here they are now acting as bad as any corporation ever did. They only care about their profit and share holders. Kind of makes them big time hypocrites. Just my humble opinion. Lesson learned? Never sell yourself short. If you’re going to be a whore, at least be a high priced whore. Stand up for yourself. Had I gone to court, I most certainly would have won. It is astonishingly easy to demonstrate to a judge how labor rates are artificially suppressed by insurers, how they manipulate the system for their corporate financial gain, and that they will do just about anything to save a buck. To be fair, I would probably do the same if I worked for Progressive or another insurance company. It is all part of their survival. When your cat eats a cute little bird, you may think it horrific, but it is only natural. And it is only natural for collision repairers to fight to survive. What is not natural is when collision repairers give up and play nice at the risk of losing everything. That’s agonizing suicide. If you’re thinking that I spend a lot of time talking about Progressive, there’s good reason. First, they deserve it. Second, I know my audience–and it’s Progressive. For this past year, Progressive Insurance has been my number one visitor to this website. State Farm has been catching up lately. They are the top visitor this month. Way ahead of everyone else. The only other entities that generate more traffic to this site are the large ISP’s like Road Runner and AOL. I’m flattered. Hopefully some of what I talk about is subliminally sinking in. Oh yeah, remember my prediction about CCC’s announcement that it would get rid of the prompts for bumper covers? I said it would be slow in coming. Well here we are a couple of months and updates later and it’s still there. Your complaints forced them to make a public acquiescence, but now that the hell raising has died down, no need to rush things. We’re still waiting CCC. Wassup? One more thing. Apparently there is a lawsuit going on in Arizona against Progressive. The plaintiffs have deposed a former Progressive employee. The deposition is interesting reading. For an inside look on the pressure and incentives to steer vehicles to network shops give it a read. It is only a partial transcript. If anyone has the entire document or a link, please send it to me or link to it in the comments section. http://www.bodyshopsolutions.com/WordPress/wp-content/uploads/2008/01/nobile-iacano-docs.pdf

-

I got a call the other from a shop owner friend asking me to help calculate his labor rate. I told him that before you calculate your labor rate, you should check your labor production (also known as effective labor rate). I asked him to total up his total tech paid hours for the month and then divide those hours by his total labor dollars sold for the month. He got back to me and was surprised that although he posted a $90.00 labor rate, his actual labor dollars per hour was only $62.00. I pointed out that this is a production problem, not a labor rate price issue. Raising labor production is equally important as understanding what your labor rate should be. In fact, ensuring your labor production is where it should be will add much needed dollars to the bottom line. One thing to consider; low labor production is not just the responsibility of the technician. You need to also take into account: Are you billing enough hours? Are you charging properly for diagnostic time? Are the techs waiting too long for parts or for the service advisors to sell jobs? Is there too much down time between jobs? Look at the entire shop operations and workflow process. Each minute increase in labor production will add much needed dollars to your bottom line.

- 4 replies

-

- 2

-

-

- Labor rate

- Effective labor rate

-

(and 2 more)

Tagged with:

-

Source: Before you raise prices, raise production

-

- Shop production

- Labor rate

-

(and 3 more)

Tagged with:

.thumb.jpg.2b345efc275b9df0af2bbb306a10a78a.jpg)